Existing inks, dyes and paints degrade and their colors fade over time; for example, warning signs or instructions on a fire extinguisher label can fade and a print of painting can lose its color due to sun exposure. But this may no longer be the case in the future.

Researchers at Kobe University’s Graduate School of Engineering have successfully developed a structural color ink from silicon nanoparticles, which is highly resistant to weathering. The new ink has many advantages that set it apart from existing structural color techniques. It utilizes Mie scattering to generate color, and it is possible to create different colors by varying the size of the nanoparticles. The extremely small size of the nanoparticles makes this ink well-suited to ultra-high resolution printing and it has potential as a colorant for a wide range of surfaces. In the future it is hoped that this technology will have diverse applications, ranging from dyes and paints to cosmetics, biotechnology, and security.

The research team consisted of Assistant Professor SUGIMOTO Hiroshi and Professor FUJII Minoru et al.

Main points

- The stable, inorganic nanoparticles result in a structural color ink with outstanding resistance to weathering.

- It is possible to create different colored ink by varying the size of the nanoparticles.

- In principle, the ink can be used for ultra-high resolution printing because individual nanoparticles a mere hundred nanometers or so in scale are the source of the ink’s color.

- Potential applications are diverse and include paints, cosmetics, biomaterials and security.

Research Background

A big problem with existing paints and dyes is that their color gradually disintegrates over time, leading to discoloration and loss of color. In recent years, ‘structural color’ has gained attention; coloration techniques that don’t use pigments. Instead, color is generated using the diffusion, interference or diffraction of light by a wavelength-specific microstructure. It is possible to generate bright colors by creating a structure consisting of many microstructures lined up in a relatively long cycle. Examples of structural coloration exhibited in nature include iridescent jewel beetles, morpho butterfly wings and peacock tail feathers. In these examples, color is generated when the microstructures reflect specific wavelengths in the white light spectrum. Due to the color originating in the structure itself, semi-permanent color can be generated as long as the structure remains unbroken. However, this technique cannot be applied to existing printing technology because the generated color greatly depends on the angle and the microstructures must be precisely constructed. In addition, even if the microstructures are maintained, the color displayed is prone to being altered by factors such as changes to the surrounding environment or the sequence becoming disordered.

Research Methodology

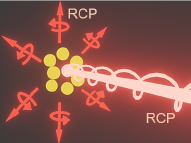

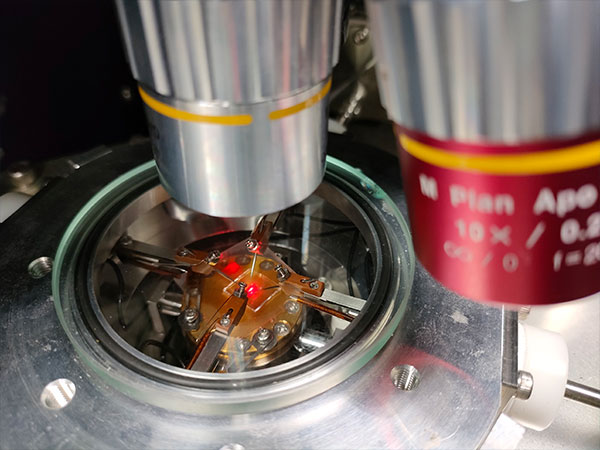

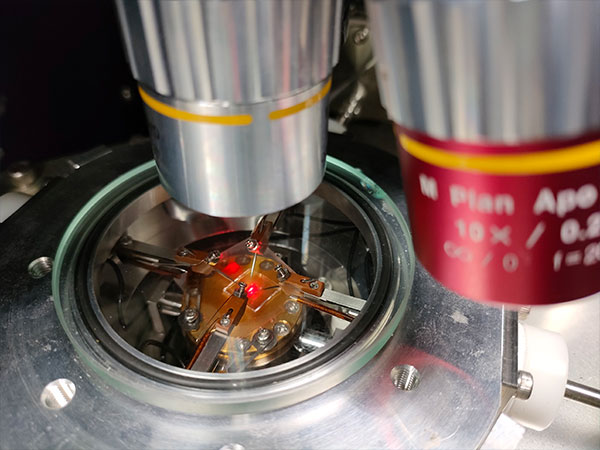

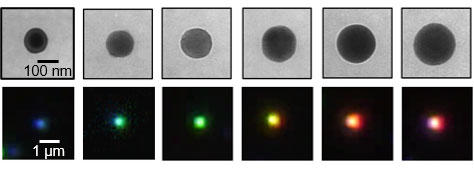

To address the issues mentioned above, the study focused on Mie scattering (*1), which is exhibited by dielectric nanoparticles. Spherical silicon nanoparticles (of approx. 100 or so nanometers in diameter) have an extremely high refractive index (4~) and strongly scatter specific wavelengths of light via Mie scattering. As the dark field optical microscopy shows in Figure 1, when the nanoparticle diameter was gradually altered from between approx. 100 nanometers and approx. 200 nanometers, the bright color generated by scattering varied depending on the size of the nanoparticle.

When nanoparticles of the same size are clustered together on a macroscale, our eyes interpret this as color. Using this technique it is possible to create a new structure for generating color that does not rely on a sequenced structure. In addition, an advantage of this method is that the color is generated using the nanoparticles themselves, not a periodic structure, so it has low angular dependence.

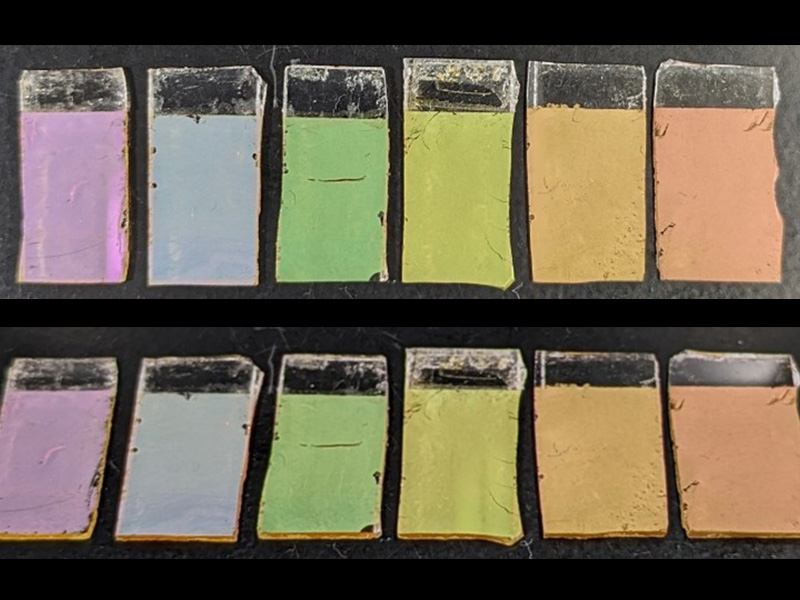

In this study, the researchers developed the following techniques; synthesis of almost spherical crystal silicon nanoparticles, dispersion of these nanoparticles in liquid, control of their size, and size selection. They succeeded in keeping the particle size distribution (average diameter ÷ standard deviation) for nanoparticles with an approximate diameter in the range of 100-200nm below 10%. As a result, they were able to create the structural color nanoparticle inks shown in Figure 2.

The developed inks could be used in a diverse range of painting and printing processes, particularly in paints that can withstand weathering. In principle, this ink can also be used for ultra-high resolution printing because every single 100nm~ nanoparticle is a source of color. With silicon’s high stability, it is also hoped that the developed technology could be applied to new inorganic pigments for use in the cosmetic and biotechnology fields.

From left, inks with an average particle diameter ranging from approx. 100nm to approx. 200nm.

Further Research

Next, the researchers plan to further improve aspects such as the brightness and reflectivity. They will scale up nanoparticle production and technologies to separate particles by diameter in order to establish a process for producing large quantities of high quality nanoparticles. In addition, they aim to realize the implementation of new colorants (such as color loss-resistant dyes and proprietary inks) through further collaboration with material/printing technology-related companies.

Glossary

1. Mie scattering

A theory developed by Gustav Mie in 1908 to describe phenomena whereby light is scattered by spherical particles (specifically dielectric particles with a high refractive index) that are similar in size to the wavelength of the light. It is possible to manipulate the resonance wavelength at which scattering occurs by altering the size of the particles.

2. Dark field optical microscopy

A microscopy method that creates an image using only the scattered light from the sample.

Journal Information

Title

“Mie Resonator Color Inks of Monodispersed and Perfectly Spherical Crystalline Silicon Nanoparticles”

DOI

10.1002/adom.202000033

Authors

Hiroshi Sugimoto,Takuma Okazaki, Minoru Fujii

Journal

Advanced Optical Materials